The SUPERtrol II (ST2) Flow Computer can be used with a variety of flowmeter types in liquid, gas, steam and heat applications. Multiple flow equations are available in a single instrument with many advanced features. The alphanumeric display offers measured parameters in easy to understand format. Manual access to measurements and display scrolling is supported

The various hardware inputs and outputs can be “soft” assigned to meet a variety of common application needs. The user “soft selects” the usage of each input/output while configuring the instrument. Consider the following illustrative examples.

The isolated analog output can be chosen to follow the volume flow, corrected volume flow, mass flow, temperature, pressure, or density by means of a menu selection. Most hardware features are assignable by this method.

The user can assign the standard RS-232 Serial Port for external data logging, transaction printing, or for connection to a modem for remote meter reading.

A Service or Test mode is provided to assist the user during start-up system check out by monitoring inputs and exercising outputs. The system setup can also be printed.

SUPERtrol-II (ST2)

Multifunction Flow Computer

Features

- EZ Setup”- Guided Setup for First Time Users

- Liquid, Gas, Steam and Heat Flow Equations

- Utility Metering

- Menu Selectable Hardware & Software Features

- Two Line LCD, OLED or VFD Display

- Internal Data Logging Option

- Isolated Pulse and Analog Outputs Standard

- RS-232 Port Standard, RS-485 Optional

- Windows™ Setup Software

- NX19 Gas Equations, Stacked DP Transmitters

- DDE Server & HMI Software Available

- Remote Metering by Wireless or Modem and TROLlink Remote Metering Software Available

Literature

Training Aids

Software

FAQ

For Pulse Inputs the Count K-Factor is equal to the number of pulses per unit of measure which is determined by the flowmeter. (This Information is typically on the flowmeter calibration sheet or stamped on the flowmeter itself).

The Rate Time is menu selectable it can be found in the “Setup Indicators Menu” under “Rate”. You will have the option of choosing Seconds, Minutes, Hours or Day which adds the appropriate multiplier into the equation.

The 4-20mA current span is the span you expect the Supertrol-2 to interpolate between. The Supertrol-2 is scaled by assigning a “Low Range” and a “High Range” to the analogous Low and High inputs of the Flow Input Menu. Let’s say that the sensor gives off an output of 4mA (milliamps) when it measures “0” ACFM and 20mA when it measures “10” ACFM. Through the keyboard you dial in “0” for 4mA (Rate Low), and “10” for 20mA (Rate High) and you have completed scaling the unit. Typically the customer will tell you the range they would like to use for their application.

The unit is shipped from the Factory with an Operator Password of “0” and a Supervisor Password of “2000” these should be tried first before giving the customer the back door code. The Factory back door code can be obtained by calling the factory or send an email.

Yes. The analog outputs are Isolated. Below you will find the specifications for the analog outputs that customers usually ask about.

The Number of Outputs are: 2

The Analog Output Type is: Isolated Current Sourcing (shared common)

Isolated I/P/C: 500 V

The Available Ranges are: 0-20 mA, 4-20 mA (menu selectable)

The Resolution is: 16 bit

The Accuracy is: 0.05% FS at 20 Degrees C

The Update Rate is: 5 updates/sec

The Temperature Drift is: Less than 200 ppm/C

The Maximum Load is: 1000 ohms

Yes. The Supertrol-2 is equipped with either a super cap or a battery backed real time clock that displays time and date. The format is: 24 hour time display and Day, Month, Year date display. (Daylight savings time is optional). |

Yes, the front panel is NEMA 4X rated. This rating is also comparable to the European standard IP65.

The user can view the Rate and Total of flow as well as the Grand Total, Temperature, Pressure, Density, Time, Date, Alarm 1 and Alarm 2. This can be accomplished by pushing the appropriate button on the front of the unit or by setting up the Scroll List to display the information desired through a scrolling display.

The Supertrol-2 has the following Listing: “CE” which is the European noise immunity standard.

The 24Vdc output is rated at 100ma maximum current draw and is overcurrent protected.

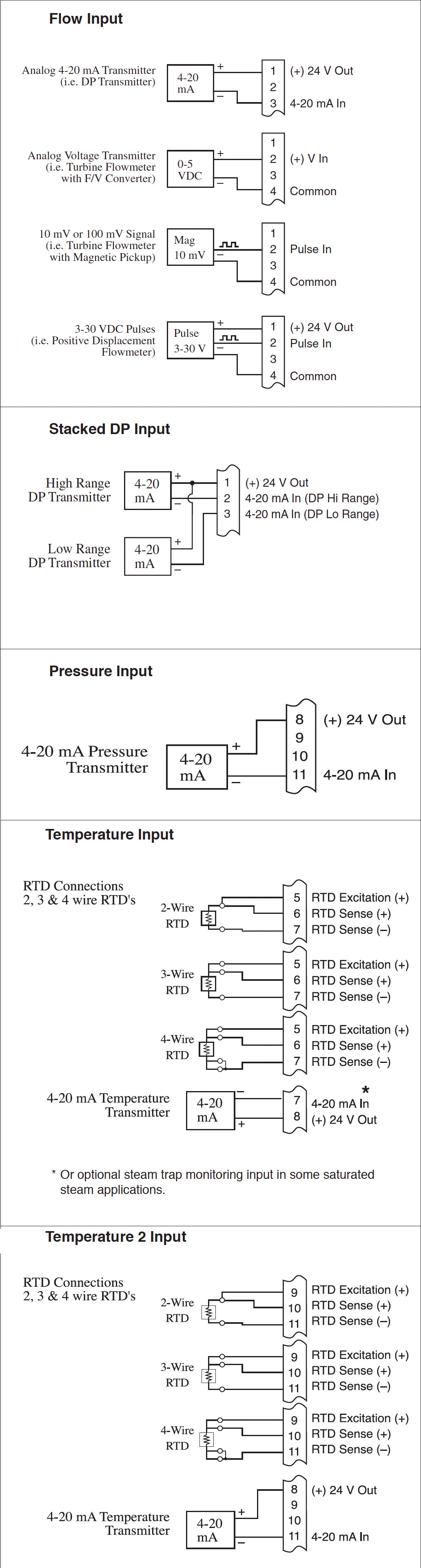

Below you will find typical wiring diagrams to help you wire a flowmeter to the Supertrol-2

|